Brand Story of SLIDEback

The Origin of SLIDEback

In order to make our product better and better, we keep improving our SLIDEback sliding door closer to have it integrate into our life as easier as possible.

WE are proud to introduce the synonym of the self-close sliding door closers - SLIDEback.

The SLIDEback was named in 2006, the product coded as SDC-280 which is our 1st generation of SLIDEback sliding door closer. The “SDC” is taken from the first letter of Sliding Door Closer, and “280” represents a body length of 28 inches.

The SDC-280 brings convenience to people's life by automatically closing the sliding door.

Provide a great solution for those who are tired of yelling at the people who don’t close the door.

The SDC-280 consists of a three-section metal telescopic tube that adopt the principle of air pressure deceleration to reduce the restoring force of the extension spring and form a force balance to achieve the purpose of automatically closing the door. No electricity is needed at all.

With such a simple structure, no electricity, no oil leakage concerns, no maintenance, simple installation, easy operation, wonderful but inexpensive product, It could upgrade the door become a self-closing automatic door, it has won a recommendation from many stores, restaurants and home users around the world.

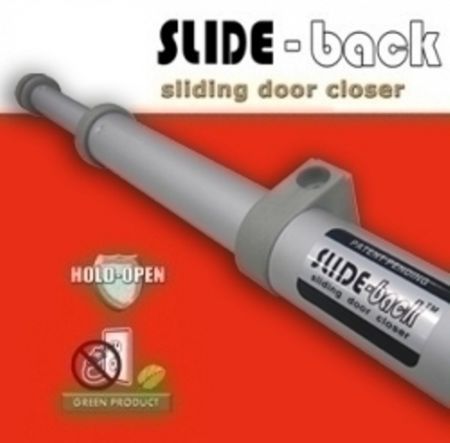

The 1st Generation of SLIDEback, Item no.: SDC-280

- 1st generation of SLIDEback

- Installation of 1st generation SLIDEback sliding door closer

The most obvious appearance is a small ball shape at the top of the tube. The shape of the Speed Control Valve is a rough recess hole at the end of the tube. Most of this generation's closers are connected to the doors by a short PIN, but this connection method is not stable enough to maintain the straight line level of the extension of the tube, and the connection is easily failed.

Although the 1st generation SLIDEback sliding door closer has a self-close function, there are many unsatisfactory issues in the quality. For example, it is hard to open the door with unstable closing speed and make the door bump into the door frame with the noise of the exhaust and so on.

The 2nd Generation of SLIDEback, Item no.: NSDC-280

- Accessories of 2nd generation

- 2nd generation of SLIDEback sliding door closer

The reason to name NSDC was that it was a NEW generation Sliding Door Closer, the N was therefore added ahead of SDC, became NSDC-280. It was launched and replaced the 1st Generation (SDC-280) in 2009.

The main improvements of the 2nd Generation are:

- In the early stage, we tried to improve the closing speed by adding magnets to control the priority of the extending tubes, but it was failed finally because of the cost concerns.

- The later alternative design was trying to improve the closing speed by placing a small steel ball inside the exhausted passage. Anyhow, the stability was still poor.

- Besides, the ugly small ball at the end of the tube was removed. An additional steel plate was developed to cover the ugly exhausted cave, beautify the appearance.

- A simple SLIDEback logo sticker was attached to the closer body to distinguish it from other similar products.

The 3rd Generation of SLIDEback, Item no.: 3SDC-280

- 3rd generation of SLIDEback sliding door closer

- Connecting bracket of 3rd generation

The reason to name 3SDC was that it was taken for the 3rd Generation Sliding Door Closer.

It was launched and replaced the 2nd Generation (NSDC-280) in 2011.

The main improvements of the 3rd Generation are:

- In terms of function, 3SDC adopted a patented design, which reduced the resistance when opening the door by the increase of the instantaneous airflow, making it easier to open the door.

- In addition to the traditional PIN connection method, the connection by fork was worked out, it contributed much stabler connection and closer’s operation.

- The Speed Control Screw was replaced by a hexagon socket machine screw which made the speed regulation more precise than before.

- 100,000-Cycle tested.

- To distinguish it from the previous old generations and the cheap counterfeit products, the traditional black color of plastic plugs was replaced by dark gray ones. Furthermore, the new exhausted valve cover was also changed to a beautiful plastic version.

- The brand marketing was officially carried out by packing the door closer in color boxes with SLIDEback brand.

The 5th Generation (5 Series) of SLIDEback, Item no.: 5SDC-702

- 5th generation of SLIDEback sliding door closer

- Brand name on SLIDEback

- Mark of speed adjustment

The 5SDC replaced the 3SDC 3rd Generation in 2016. Also, was re-defined as 5 Series in August 2019.

The main improvements of 5 Series are as below:

- The airflow was improved by patented Differ-Kinetic Technology; contributed more SMOOTH closing speed, and less leakage of lubricating oil.

- Meanwhile, 5 Series continues to use the 3SDC’s patent of the less force required for door opening,

- Upgraded adjustable Fork-connection MBA and more accessories like MBG MBL were developed out to apply for different frameless glass and framed doors.

- Provide the Hold-open function by optional HOM accessory.

- To enhance the overall texture of the product, we put the SLIDEback logo on closer by screen printing, instead of a sticker.

- To distinguish 5 Series from previous old generations and cheap copied products, the color of all the plastic plugs is entirely changed to milk-white. Meanwhile, the color of Speed Control Screw is chrome plated instead of previous dyed black.

6 Series SLIDEback, Item no.: 6SDC-693

- 6th generation of SLIDEback sliding door closer

- 6th Series SLIDEback sliding door closer

- Decorative casing

Launched in August 2019.

The birth of the 6 Series is not to replace the 5 Series, but to increase the possibility of more applications for various types of sliding doors by different installing ways.

6 Series is positioned as higher level series of SLIDEback sliding door closer.

The main features include:

- Easier installation by new design of Mounting Clip brackets.Patented connecting design provides various applications for different sliding barn doors, frameless glass sliding doors, timber sliding doors, metal sliding doors, framed sliding doors, double doors and bypass doors.The longer newly designed square casing is included to improve the overall visual aesthetics. The longer casing can be cut short to have the same length as the door width or per your wanted length to hide the door closer's body completely.The slim closer body offers the possibility to be installed in the limited space.The front Speed Control Valve provides the maximum convenience while regulating closing speed.Quick connection and separation switching bar design to have a door with or without auto-closed function.Optional rail style semi concealed Hold-open accessory.

4 Series SLIDEback, Item no.: 4SDC-400

- 4th generation of SLIDEback sliding door closer

- SLIDEback slding door closer with decorative casing

- Installed on 3 panels sliding door

Launched in September 2019.

4 Series design combines the basic features of both 5 and 6 Series with an extra extension tube. Total 4 extending tubes design offers the possibility to apply for 3 panels sliding doors.

The main features include:

- The patented connecting design provides various applications for different sliding doors, but mainly for 3 panels sliding doors.

- Quick connection and separation switching bar design to have a door with or without auto-closed function.